The following is a detailed analysis of the system:

Role and necessity of the system

- Protecting equipment: removing solid impurities (e.g. sand, metal debris, mud residue, etc.) from fracturing fluid, preventing key equipment such as high-pressure pumps, pipe sinks, injection tools, etc., from being worn out or clogged.

- Optimize fracturing effect: avoid impurities from entering the formation, resulting in reduced fracture conductivity or uneven proppant distribution.

- Improve operational efficiency: reduce the downtime of equipment maintenance caused by impurities, and lower operational costs.

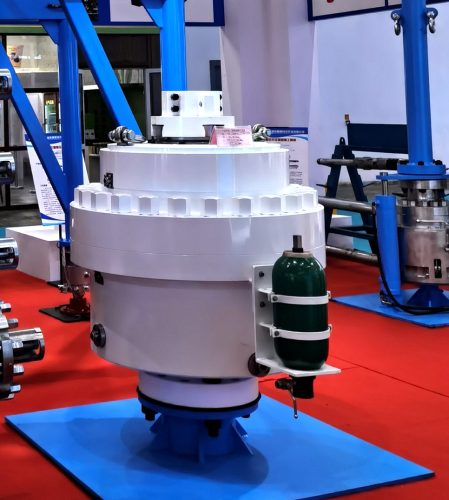

Desanding System

This system is a product provided by SCOTON for a hydraulic fracturing service company in the United States, which can remove sand and particulate matter from fluids. Separate oil and gas from sand. Oil and gas rise, sand is blocked by baffles and loses energy, falling into the pipeline below.

The working pressure is 15000PSI, and it is designed with a bracket for easy transportation and installation.

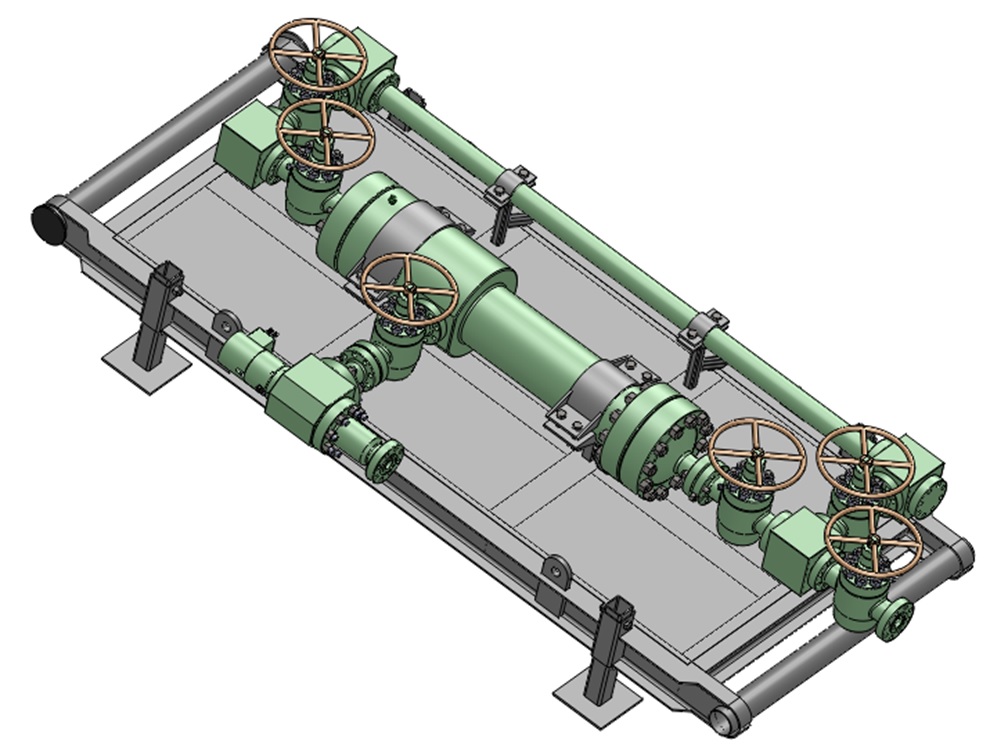

Filtration System

This system is a product provided by SCOTON for a fracturing service company in the United States, which can filter and retain large particulate matter and can be backwashed. After the completion of layered fracturing, filter and recover the fracturing sand. The working pressure is 15000PSI, and it is designed with a base for easy transportation and installation.